CERTIFICATIONS

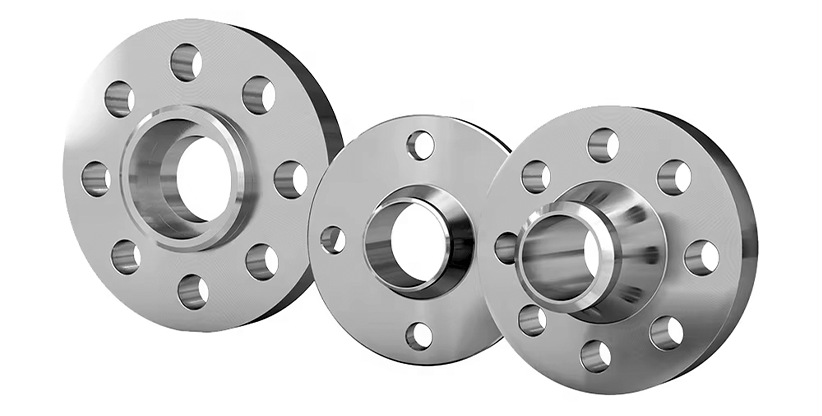

Manufacturing a Full Line of Stainless, Duplex, and Nickel Alloy Flanges in Our ISO 9001 Certified Facility

MFC Flange has a storied history and an incredible reputation globally for providing high quality flanges all from Sealy, Texas. MFC Flange is a global manufacturer of only the highest quality flange, rings, and forgings used in a variety of fields such as the petrochemical industry, nuclear power industry, offshore industry, as well as extreme environments.

The addition of MFC Flange, Inc. into the Newman Flange & Fittings in 2025 family of companies is a natural fit, aligning seamlessly with our shared commitment to delivering high-quality flange & forging products to industrial processing industries.

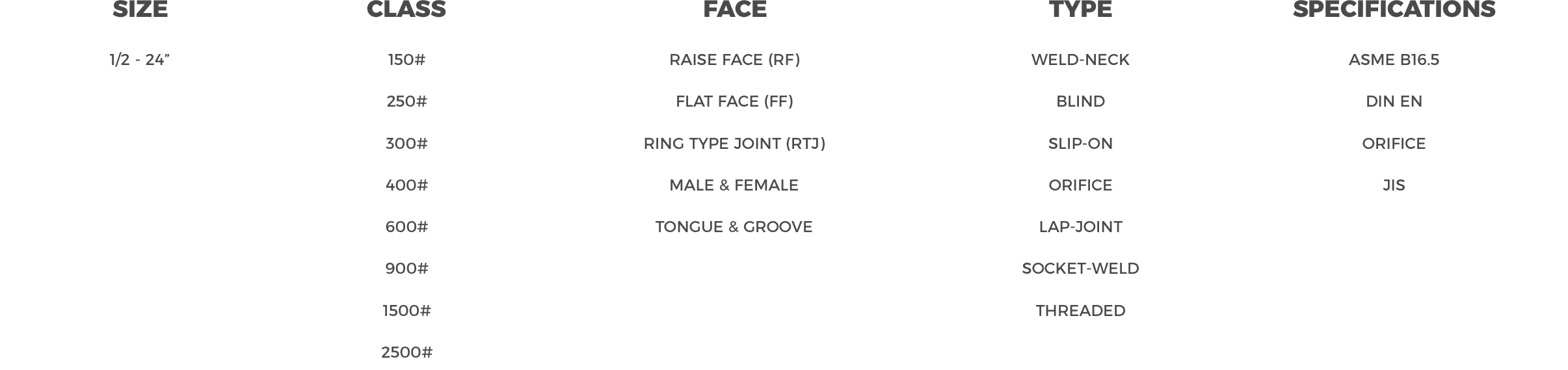

Our domestic and DFARS compliant inventory of 40 different material types allows MFC Flange to support a wide range of end-use applications, within the domestic USA market and worldwide. The breadth of our forging capabilities makes MFC a reliable source of unique needs. Our machine shop produces both small and large quantities and can do so within even the most intricate dimensional specifications. All our flange & forging products are produced according to standards set by ANSI, ASME, ASTM, DIN, DIN EN, ISO 9001 and PED.

Our experienced staff is prepared to respond to your needs and strives to set the standard for customer service. We also understand that downtime is an expensive proposition, so we use on-time delivery as a key metric promoted throughout our entire operation. We take pride in our ability to respond to time sensitive requirements, using expedited production and shipment processes to match those urgent orders.

material

grades

material

SIZES

material grades

material sizes

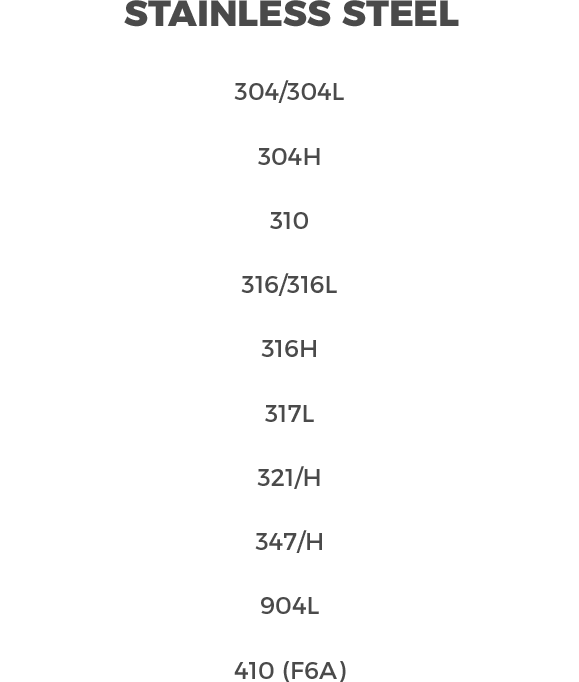

Stainless

Flanges

A stainless-steel flange is a type of pipe flange made from stainless steel, a corrosion-resistant alloy containing chromium and nickel. These flanges are used to connect pipes, valves, pumps, and other equipment in industries such as oil and gas, chemical processing, water treatment, and food processing.

Nickel Alloy

Flanges

Nickel alloy flanges demonstrate excellent resistance to corrosion, exceptional high temperature strength and other unique properties, such as shape memory. MFC Flange has been manufacturing corrosion resistant nickel alloy flanges for many years. We have developed the knowledge and skills to meet the needs of our global customer base. Our flanges are required for increasingly demanding applications spanning a variety of markets including, but not limited to: Defense, Agriculture, Industrial, Power Generation, Petrochemical, and Transportation.

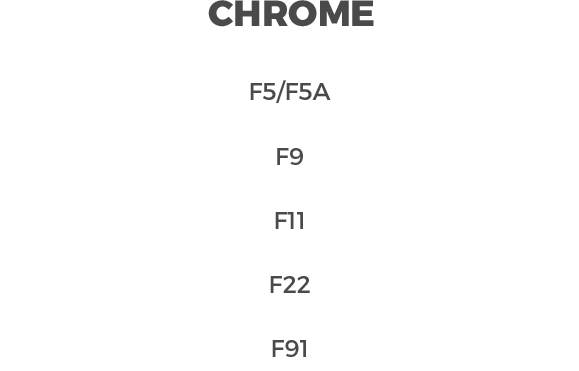

Chrome Flanges

A chrome flange is a metal flange coated with a layer of chromium, designed to enhance its surface with increased hardness, durability, and resistance to corrosion. This makes it particularly suitable for demanding environments requiring high strength, durability, and resistance to corrosion, such as in industrial systems exposed to extreme conditions.

Duplex Flanges

A duplex flange is a type of pipe flange made from duplex stainless steel, which consists of a mixed microstructure of austenite and ferrite. This combination provides high strength, excellent corrosion resistance, and durability, making duplex flanges ideal for applications in the oil and gas, chemical, and marine industries.

Capabilities

As a premier specialty forging manufacturer, we work closely with our clients to ensure their requirements and expectations are fully met. MFC Flange can provide a full range of ANSI/ASME forgings for flange products in a variety of material grades. Whether you need a large quantity of parts for your inventory, or a few pieces on a quick delivery for a project, we can utilize our forging assets to provide different solutions.

- Closed-die & Open die forging

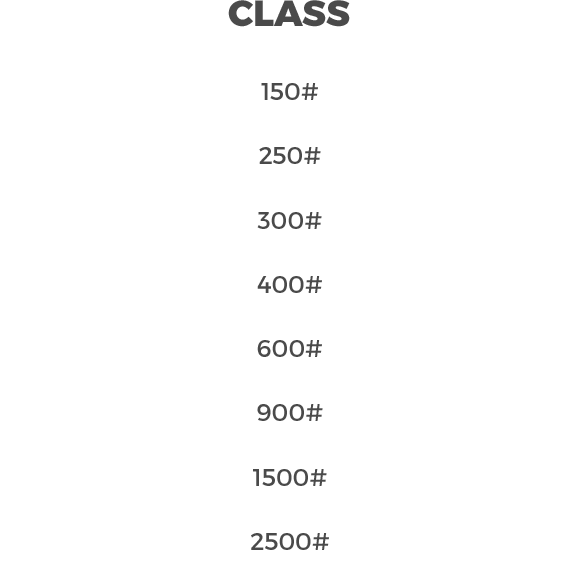

- Forgings for piping products up to 2500# ANSI pressure class

- Mechanical, hydraulic and hammer presses – from 300 to 1,000 ton

- Extensive range of inventoried raw materials-including Nickel Alloys, Stainless Steel, Duplex & Chrome Alloys

From rough machined to finished products, MFC Flange has the machine tools to produce and support industry standard products as well as some complex components. Our machining services are backed by ASME, ISO 9001, PED certifications, along with other industry standards as required.

- Turning

- Milling

- Drilling

We offer advanced in-house heat-treating capabilities to help ensure the highest possible quality standards throughout the thermal process, including:

- Annealing

- Solution Heat Treatment

- Normalizing

- Stress relief

- Water quenching

From general and advanced material testing, MFC Flange offers testing and onsite inspection to ensure quality and reliability for our customers. Our testing services are backed by ASME and ISO 9001 certifications, along with other industry standards as required.

- Factory Acceptance Testing (FAT), which can include dimensional, pressure, interface/fitment

- Mechanical testing

- PMI (Positive Material Identification)

- Chemical analysis

- Tensile testing

- Grain Size

- Corrosion

- Micro-Structure/Ferrite

- Hardness Testing (BHN)

- Charpy impact testing

- NDE (UT, LP)

GET QUOTE

We look forward to hearing from you! If there are any questions or concerns we can help with, please feel free to reach out via email or give us a call directly at 1 (979) 627-6222